| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Pride

Model Number : METCUT 300/400/500

Place of Origin : China

MOQ : 1

Price : negotiate

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 1000/month

Delivery Time : 15-25days

Packaging Details : wooden case

cutting diameter : 140 mm

Rotating speed : 100-3000 rpm

VFD Motor : 5.5 KW

Power supply : 380V, 50 Hz, three phases

Dimensions : 1450 x 1400 x 1850 mm

Weight : about 1900 Kg

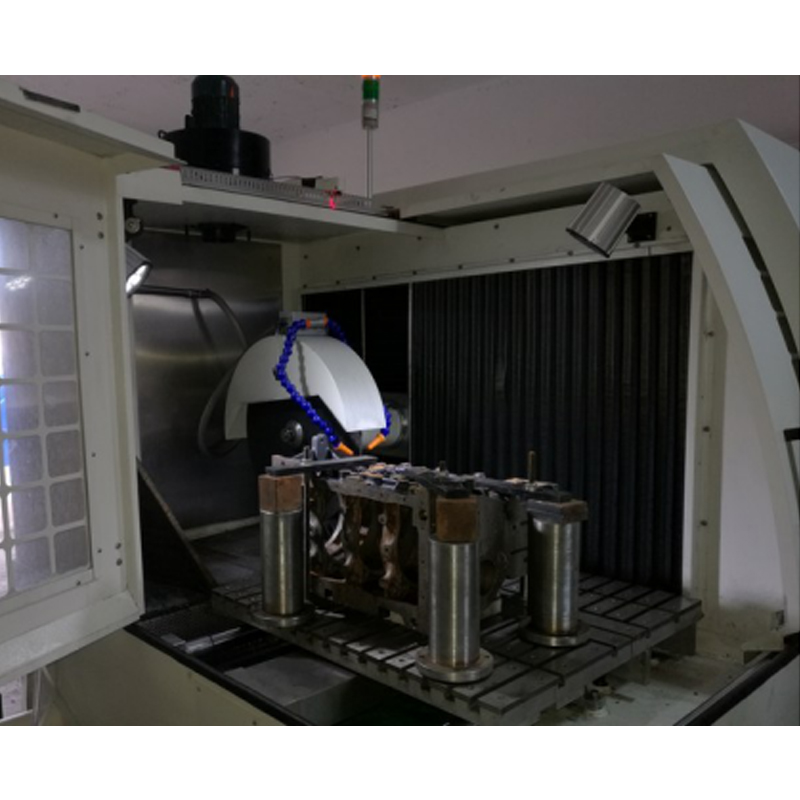

ABRASIVE CUTTER METCUT 300 Metallographic Equipment Metallographic specimens Abrasive Cutting Machine

ABRASIVE CUTTER METCUT 300 is a kind of PLC controlled automatic metallographic specimen cutting machine. The X, Y, Z directions can be controlled precisely and automatically. It has intelligent cutting ability which makes it possible to change the feeding rate according to the hardness changing of material, in this way, it can realize fast cutting effect and variable frequency controlling of cutting speed. It features very high reliability and controlling ability. It is the ideal large specimen cutting machine which can be used in colleges, laboratories, car manufacturing, steel manufactories, material research institutes and so on.

Features:

● Equipped with Manual Pulse Generator which is convenient for quick positioning.

● Various cutting data can be displayed on touch screen, HMI (Human Machine Interface) controlling.

● Four kinds of cutting types of swing cutting, continuous cutting, to-and-fro cutting and speed-changing cutting. Cutting speed can be changed according to different hardness materials so as to realize fast cutting. It can reach 15mm/min. cutting speed on steel round bar specimen.

● Full-closed structure is adopted in working area. Large viewing window is provided on transparent safety shield of cutting chamber.

● Draught fan ensures high efficiency air exhaust for the various steam and smog produced during cutting process, and this increases the brightness and legibility of cutting chamber.

● Specially designed for the cutting of large work piece. Slide door and hinged door make it possible for the fixing of large work piece from three different directions (up-left-front).

● Special lubricant liquid cooling tank with magnetic filter. Stainless working table. Water-jet type cleaning system. LED lighting system. Quick clamping vices.

● 5.5 KW VFD motor linked to cutting disc directly. Stepless speed changing.

● Humanization design, precise positioning, low noise, convenient operation, beautiful appearance, reliable and safe performance.

Technical specifications

● Manual / Automatic mode can be chosen at will.

● Three-axis simultaneous motion.

● 10” industrial grade touch screen controlling.

● Manual Pulse Generator operation is available.

● Max. cutting diameter: 140 mm

● Rotating speed: 100-3000 rpm stepless adjustable

● Cutting disc diameter: 400 x 3 x 32 mm

● Feeding speed: 0-15mm / min. (User may modify the speed as per the actual need)

● Worktable size: 500 x 600 mm (X * Y)

● Max. travel of Y-axis: 450 mm

● Max. travel of Z-axis: 250 mm

● Max travel of X-axis: 150 mm

● Clamping vices: opening 200 mm

● Cooling water tank: 150L

● VFD Motor: 5.5 KW

● Power supply: 380V, 50 Hz, three phases

● Dimensions: 1450 x 1400 x 1850 mm

● Weight: about 1900 Kg

ABRASIVE CUTTER METCUT 400

ABRASIVE CUTTER METCUT 400 is a kind of PLC controlled automatic metallographic specimen cutting machine. The X, Y, Z directions can be controlled precisely and automatically. It has intelligent cutting ability which makes it possible to change the feeding rate according to the hardness changing of material, in this way, it can realize fast cutting effect and variable frequency controlling of cutting speed.

It features very high reliability and controlling ability. It is the ideal large specimen cutting machine which can be used in colleges, laboratories, car manufacturing, steel manufactories, material research institutes and so on.

Features:

· Equipped with Manual Pulse Generator which is convenient for quick positioning.

· Various cutting data can be displayed on touch screen, HMI (Human Machine Interface) controlling

· Four kinds of cutting types of swing cutting, continuous cutting, to-and-fro cutting and speed-changing cutting. Cutting speed can be changed according to different hardness materials so as to realize fast cutting. It can reach 15mm/min. cutting speed on steel round bar specimen.

· Full-closed structure is adopted in working area. Large viewing window is provided on transparent safety shield of cutting chamber.

· Draught fan ensures high efficiency air exhaust for the various steam and smog produced during cutting process, and this increases the brightness and legibility of cutting chamber.

· Specially designed for the cutting of large work piece. Slide door and hinged door make it possible for the fixing of large work piece from three different directions (up-left-front).

· Special lubricant liquid cooling tank with magnetic filter. Stainless working table. Water-jet type cleaning system. LED lighting system. Quick clamping vices.

· 7.5 KW VFD motor linked to cutting disc directly. Stepless speed changing.

· Humanization design, precise positioning, low noise, convenient operation, beautiful appearance, reliable and safe performance.

Technical specifications

● Manual / Automatic mode can be chosen at will.

● Three-axis simultaneous motion.

● 10” industrial grade touch screen controlling.

● Manual Pulse Generator operation is available.

● Max. cutting diameter: 170 mm

● Rotating speed: 100-3000 rpm stepless adjustable

● Cutting disc diameter: 450 x 3.5 x 32 mm

● Feeding speed: 0-15mm / min. (User may modify the speed as per the actual need)

● Worktable size: 550 x 650 mm (X * Y)

● Max. travel of Y-axis: 450 mm

● Max. travel of Z-axis: 250 mm

● Max travel of X-axis: 150 mm

● Clamping vices: opening 300 mm

● Cooling water tank: 200L

● VFD Motor: 7.5 KW

● Power supply: 380V, 50 Hz, three phases

● Dimensions: 1500 x 1450 x 1900 mm

● Weight: about 2200 Kg

ABRASIVE CUTTER METCUT 500

ABRASIVE CUTTER METCUT 500 is a kind of PLC controlled automatic metallographic specimen cutting machine. It adopts MITSUBISHI brand controlling system and servo motor, the X, Y, Z directions can be controlled precisely and automatically. It has intelligent cutting ability which makes it possible to change the feeding rate according to the hardness changing of material, in this way, it can realize fast cutting effect and variable frequency controlling of cutting speed. It features very high reliability and controlling ability. It is the ideal large specimen cutting machine which can be used in colleges, laboratories, car manufacturing, steel manufactories, material research institutes and so on.

Features:

· Equipped with Manual Pulse Generator which is convenient for quick positioning.

· Various cutting data can be displayed on touch screen, HMI (Human Machine Interface) controlling.

· Four kinds of cutting types of swing cutting, continuous cutting, to-and-fro cutting and speed-changing cutting. Cutting speed can be changed according to different hardness materials so as to realize fast cutting. It can reach 15mm/min. cutting speed on steel round bar specimen.

· Full-closed structure is adopted in working area. Large viewing window is provided on transparent safety shield of cutting chamber.

· Draught fan ensures high efficiency air exhaust for the various steam and smog produced during cutting process, and this increases the brightness and legibility of cutting chamber.

· Specially designed for the cutting of large work piece. Slide door and hinged door make it possible for the fixing of large work piece from three different directions (up-left-front).

· Special lubricant liquid cooling tank with magnetic filter. Stainless working table. Water-jet type cleaning system. LED lighting system. Quick clamping vices.

· ABB 11 KW VFD motor linked to cutting disc directly. Stepless speed changing.

· Humanization design, precise positioning, low noise, convenient operation, beautiful appearance, reliable and safe performance.

Technical specifications

● Manual / Automatic mode can be chosen at will.

● Three-axis simultaneous motion.

● 10” industrial grade touch screen controlling.

● Manual Pulse Generator operation is available.

● Max. cutting diameter: 180 mm

● Rotating speed: 100-3000 rpm stepless adjustable

● Cutting disc diameter: 500 x 4 x 32 mm

● Feeding speed: 0-15mm / min. (User may modify the speed as per the actual need)

● Worktable size: 700 x 800 mm (X * Y)

● Max. travel of Y-axis: 750 mm

● Max. travel of Z-axis: 290 mm

● Max travel of X-axis: 150 mm

● Clamping vices: opening 400 mm

● Cooling water tank: 250L

● VFD Motor: 11 KW

● Power supply: 380V, 50 Hz, three phases

● Dimensions: 1650 x 1600 x 1900 mm

● Weight: about 2500 Kg

|

|

5.5 KW VFD Motor Abrasive Cutting Machine For Colleges / Laboratories Images |